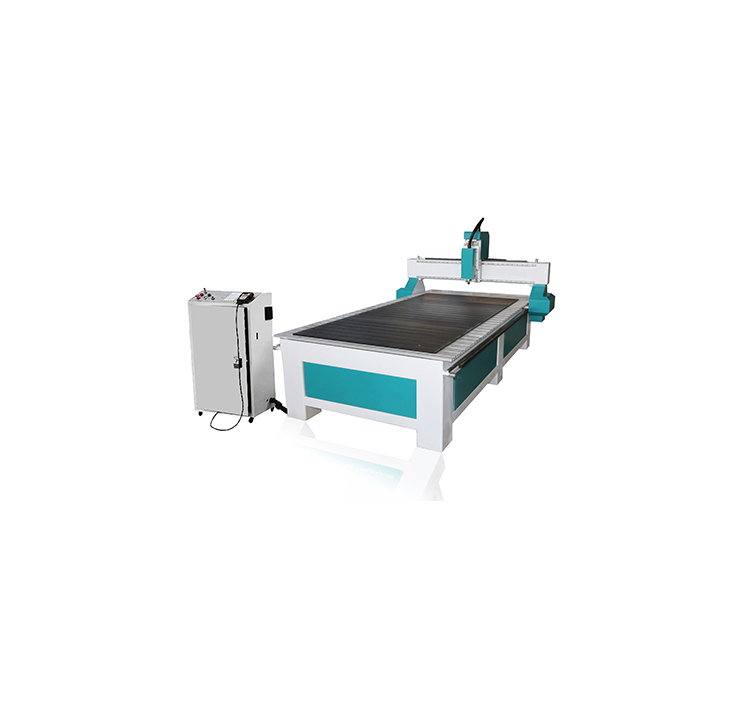

TopTek Signage CNC Router

Heavy Duty 8x4feet CNC Routers for Sign Shop and Advertising Industry.

- Working Size: 2500 x 13000 mm

- Spindle Speed: 18000RPM Air Cooled

- Option Voltages: Single & Three Phase

- Spindle Power: 4.5kw

- VFD Inverter: 5.5Kw

- Table: Aluminum T-Slot

Applications: Sign making, Acrylic, MDF, ACP sheets, Woodworking, Kitchen Cabinets, Furniture etc.

Description

Introduction of CNC Router:

Welcome to the epitome of precision and power in the world of CNC Router. Our TopTek Signage CNC Router is more than a machine. it’s a symbol of innovation and craftsmanship. Let’s explore the exceptional features that set our CNC router apart by promising you an unparalleled journey into the world of creative possibilities.

| Model | TOPTEK Signage CNC Router |

| Working Area (XYZ) | 2500x1300x80mm (118x59x5.8 inches) |

| Spindle Power | 4.5kw |

| Spindle Speed | 18000RPM Air Cooled |

| VFD Power | 5.5Kw |

| Working Table | Aluminum T-Slot |

| Drive Control System | Hybrid Servo Motors |

| Operational Controlling | Offline Handheld DSP Control |

| Z Working Height | 80mm (5.8 inches) |

| Graphic Format Supported | PLT, BMP, DXF, DST, AI, TIF, GIF, JPG, PNG |

| Software Format Supported | AutoCAD, CorelDraw, Artcut, Artcam |

| Electric System | Omron – Japan |

| Lubrication System | Semi-Automatic Lubrication System |

| Electric Cable System | Germany Igus cables |

| Interface | USB & Offline USB Stick/pen Drive |

| Voltage | AC110V/220V/380V/480V(±10%) Single/Three Phase |

| Working Environment | Temperature 20-30℃ Humidity 45-65% |

| Machine Size & Weight | 3520*2280*1880mm, (138x90x74in) 1300 kgs (2866 lbs) |

| Packing Size & Weight | 3680x2330x1950mm, (145x92x77in) 1500 kgs (3306 lbs) |

Most Powerful Spindle Power

At the heart of our CNC router beats a 4.5KW Air Cooled Spindle. A powerhouse designed to redefine your cutting and carving experiences. Precision, speed, and reliability come together to empower your creative endeavors with unparalleled Performance.

Expansive Working Area

Dream big, carve big. With a generous XY 1300 x 2500 & Z 200mm working area. our CNC router opens up a world of possibilities for your projects. From intricate designs to larger-than-life creations, this machine is your gateway to limitless creativity.

Premium Components for Peak Performance

Experience the excellence of Japanese OMRON Switches and Igus German wiring Cables. Every component is chosen for its reliability and precision, ensuring your CNC router operates at its peak performance. The Offline DSP Operational Control System adds another layer of convenience to your workflow, allowing you to separate work environment away from computer or designing room.

Sturdy Table Surface Structure

Craft with confidence on our CNC router’s T-Slot Extrusions Table Surface Structure. Stability is paramount, ensuring that your materials stay secure during every cut and carve. This is not just a machine; it’s a promise of reliability in every project you undertake.

Flexible Voltage Options

Adaptability is key. Our CNC routers seamlessly adjusts to your needs with a Single Phase AC110/220/380V/50HZ/60Hz working voltage. Regardless of your power requirements, this machine is ready to deliver consistent and reliable results.

Convenient Weight Distribution

Weighing in at a net weight of 1100kg and a gross weight of 1300kg, our CNC router embodies both power and portability. Move it where you need it, secure in the knowledge that its weight distribution ensures stability during operation.

Diverse Applications

This CNC router is more than just a tool; it’s a versatile companion for various applications. From sign-making to working with materials like acrylic, MDF, ACP sheets, and more, its capabilities are as diverse as your creative visions.

Conclusion:

Elevate your craftsmanship with our 4.5KW CNC Router – a symphony of power, precision, and versatility. From the robust spindle to the expansive working area, every feature is designed to amplify your creative potential. Choose innovation, choose power, choose us – where precision meets limitless possibilities.

More about CNC routers, What is cnc router? CNC Router roll in Woodworing cnc

Computer Numerical Control (CNC) routers have revolutionized the woodworking and LED sign board industries, offering precision, efficiency, and versatility in the production process. These powerful machines have become indispensable tools for manufacturers, craftsmen, and designers seeking to push the boundaries of creativity while ensuring accuracy in their projects.

In the realm of woodworking, CNC routers have become the backbone of modern workshops. Traditional woodworking methods often relied on manual labor and intricate craftsmanship, which, while producing beautiful pieces, were time-consuming and susceptible to human error. CNC routers have changed this narrative by automating the cutting, carving, and shaping processes with unparalleled precision.

Woodworkers benefit from the ability of CNC routers to translate digital designs into intricate wooden masterpieces. Whether it’s crafting intricate furniture pieces, decorative moldings, or customized cabinetry, these routers excel in reproducing complex designs with consistency. The precise movements and cutting capabilities of CNC routers allow woodworkers to achieve intricate details and patterns that would be nearly impossible to replicate consistently by hand.

Furthermore, CNC routers empower woodworkers to experiment with various materials beyond traditional woods. They can efficiently work with materials like MDF (Medium-Density Fiberboard), plywood, and even certain plastics, broadening the range of possibilities for creative projects. This flexibility enhances the adaptability of CNC routers for diverse applications within the woodworking industry.

In the LED sign board industry, CNC routers play a crucial role in the production of high-quality and visually appealing signage. These machines excel in carving and engraving detailed designs onto a variety of materials, including acrylics and plastics commonly used in LED sign boards. The precision of CNC routers ensures that intricate logos, text, and graphics are accurately reproduced, meeting the exact specifications of the design.

LED sign board manufacturers leverage CNC routers to create three-dimensional signage, adding depth and dimension to their products. The ability to precisely cut and carve materials allows for the incorporation of intricate details that enhance the visual impact of the signage. Additionally, CNC routers enable the efficient production of large quantities of signs with consistent quality, meeting the demands of commercial projects and signage installations.

The integration of CNC technology in both woodworking and LED sign board industries has not only increased efficiency but also expanded the possibilities for creative expression. Designers and craftsmen can now explore intricate and elaborate designs that were once challenging to achieve manually. The automation of repetitive tasks also allows skilled artisans to focus on the artistic aspects of their work, pushing the boundaries of craftsmanship.

In conclusion, CNC routers have become indispensable tools in the woodworking and LED sign board industries, offering precision, efficiency, and creative freedom. As technology continues to advance, these machines will likely play an even more significant role in shaping the future of these industries, empowering artisans to bring their visions to life with unparalleled accuracy and speed.

Enquiry Now

Error: Contact form not found.